The company is involved in the semiconductor and solar power businesses, company’s two cornerstones of our business".

Semiconductor Business

Through over 30 years of experience in offering the foundry service, Phenitec has built up proven records of mass production of a wide variety of products.

The knowledge and technological capabilities we have gained to date have made it possible for us to keep flexibly focusing on the various needs of our customers.

Business Area

Pattern design

With combinations of devices, we design patterns that meet your requirements.

Photomask data production

Photomasks are produced from our photomask data.

Device formation

The following processes are repeated.

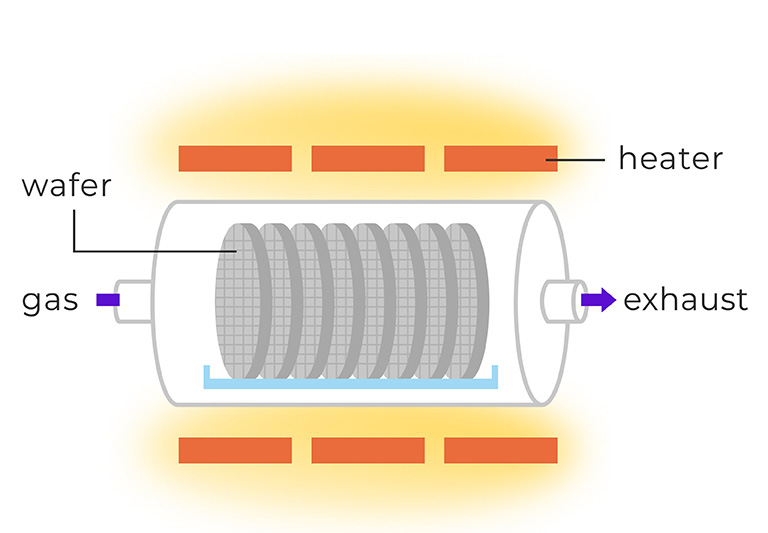

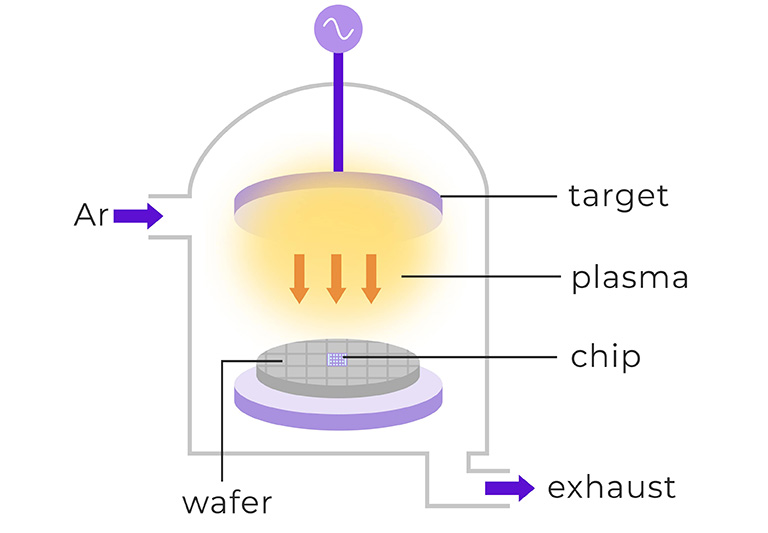

Thin-film formation

A thin film for the pattern is produced in a thermal oxidation furnace to form a silicon oxide film, etc.

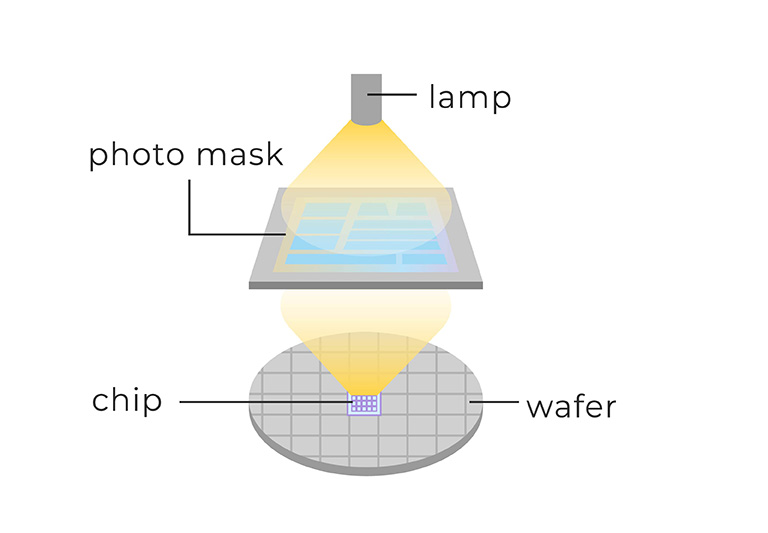

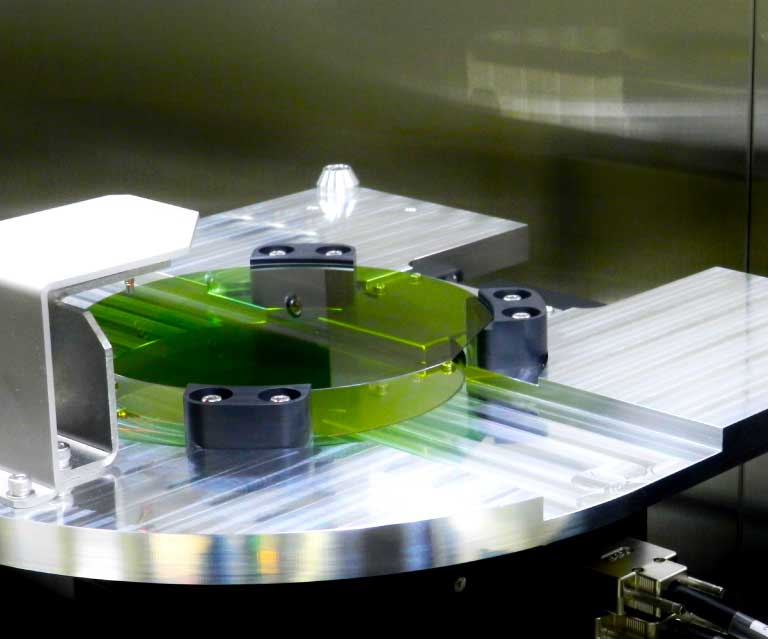

Patterning

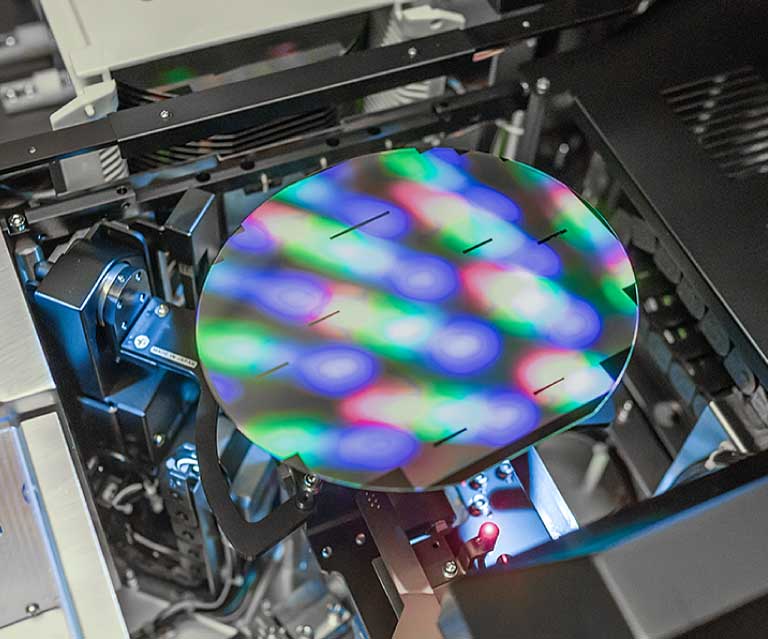

A wafer is patterned by exposing the photoresist coated on the wafer to ultraviolet light, through the photomask pattern.

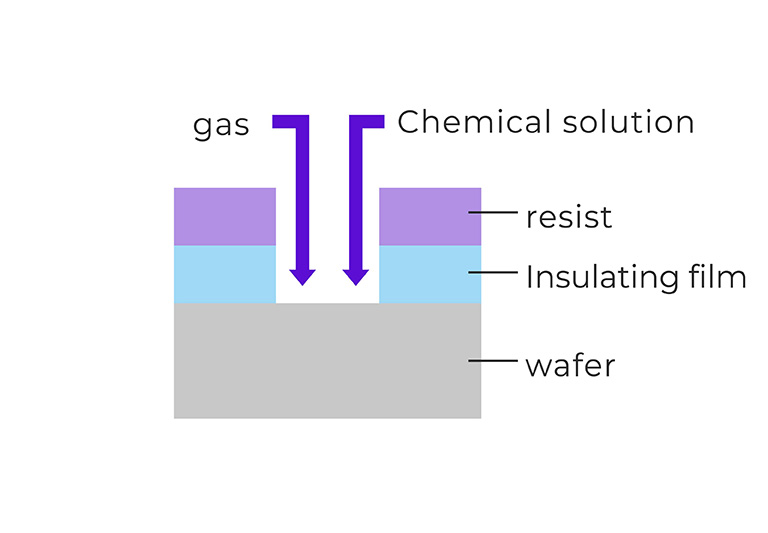

Etching

The thin film is processed along the photoresist pattern via the reaction of chemicals and gases.

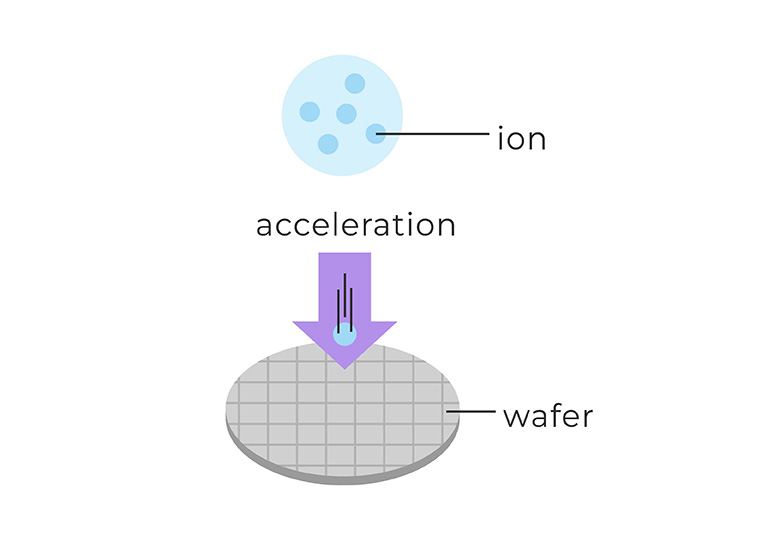

Ion implant

Electrical properties are changed by ion implantation.

Diffusion, CVD, CMP, etc.

Electrode formation

A film of aluminum or other metal is formed on the wafer to serve as device-to-device wiring.

Passivation, back grinding,

backside electrode formation, etc.

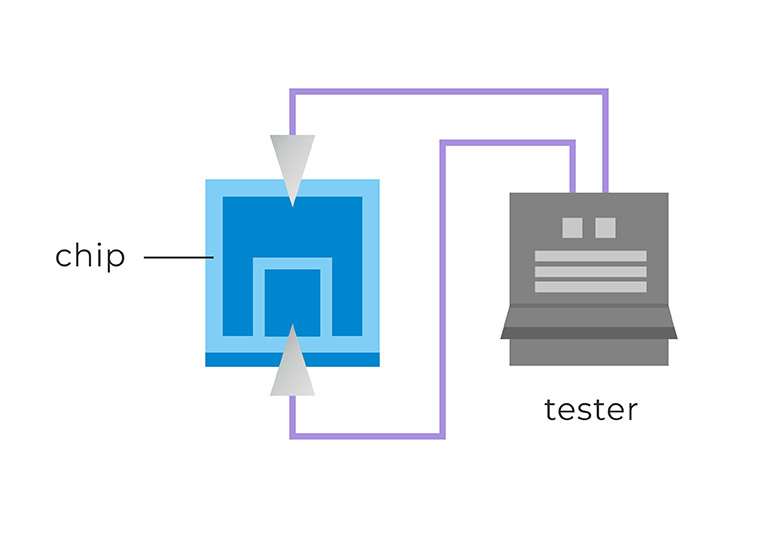

Wafer inspection

Electrical characteristics and appearance are inspected.

Faulty chips are identified with marking.

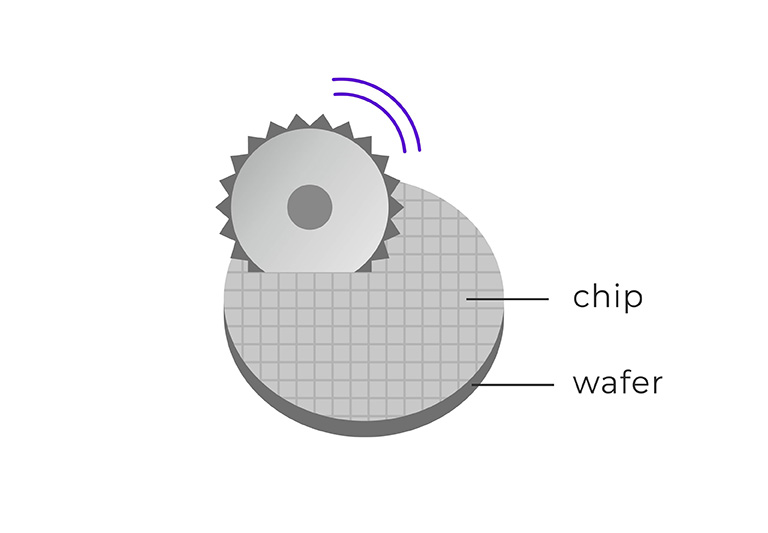

Dicing

A wafer is cut to separate it into individual chips.

Package encapsulation

Chips are encapsulated in molded resin or other packages at the customers' plant, laser-marked with the product name, etc., and sorted for quality at the final test.

Foundry Production Types

01

Original

Integrated process

02

Foundry

Integrated process

Original- In addition to offering proposals with existing products, Phenitec develops custom products that will be optimally designed and manufactured based on your requests.

Integrated process

Foundry- Using Phenitec’s own processes and conditions, we undertake the manufacturing of products that you design. Production using your own processes and conditions is also possible.

Partial Works

Foundry- Phenitec undertakes some of your product manufacturing processes.

CMOS Shuttles

Foundry- Phenitec offers a CMOS shuttle service that can be used jointly by multiple customers or for the development of multiple prototype products.

Products/Services

Learn more about Phenitec’s manufacturing capacities, foundry service and CMOS shuttle service.

Learn more about Phenitec’s SiC devices. Please feel free to contact us if you have any question about Phenitec's SiC foundry service.

Feel free to contact us using the form below for an inquiry or quotation request about products and manufacturing

Solar Power Business

Phenitec’s solar power business covers everything from sales, installation and inspection for photovoltaic systems to rechargeable battery systems, and all-electric home products.

Since the start of business in 2009, we have sold and installed numerous systems for both corporate customers and residential customers.

Phenitec’s solar power business continues its commitment to boosting the use of renewable energy to help realize a sustainable society.

Contact us for any questions about our products, services, recruitment, or anything else!